Choosing the right cutting tool for your CNC router can be the difference between a clean, professional finish and a frustrating project full of rough edges and tear-out. With so many different types of bits available, it’s easy to feel overwhelmed. Should you use a flat end mill or a ball nose? What about compression bits? And where do V-bits fit in?

This guide breaks down the most common CNC router cutting tools, explains when to use each, and clears up the confusion around CNC router bits vs. end mills. By the end, you’ll know which tools to keep in your shop and how to apply them to your projects.

In This Guide

- Why Cutting Tool Choice Matters

- Flat End Mills

- Ball Nose End Mills

- Upcut, Downcut & Compression Bits

- V-Bits

- CNC Router Bits vs End Mills

- Quick Reference Table

- Building a Starter Set

Why Cutting Tool Choice Matters

A CNC router’s accuracy depends on three things:

- Machine stability

- CAM toolpaths

- Cutting tool selection

Even if your machine and software are dialed in, the wrong bit can ruin the result. Using an upcut when you need a downcut will leave chipped veneers. Choosing a flat end mill for a 3D relief carve will produce blocky contours instead of smooth surfaces.

The good news? You don’t need a massive collection of bits. A handful of well-chosen tools will cover most woodworking, plastic cutting, and engraving tasks. If you want to stock up, TwoTrees offers CNC router bit sets and variety packs that give you all the essentials in one box.

Flat End Mills

What it is: A flat end mill has a square tip that produces a flat bottom when cutting. It’s the “default” bit most CNC beginners start with.

Best for:

- Pocketing (removing large areas of material)

- Slot cutting

- Edge profiles

- Simple 2D contouring

Materials: Wood (softwoods, hardwoods, MDF, plywood), plastics (acrylic, HDPE, polycarbonate), and some soft metals (aluminum, brass) with conservative speeds/feeds.

When to use it: Any time you want sharp corners and flat bottoms. Great for pockets for inlays or routing out a sign background.

Helpful pick: TwoTrees Endmill Variety Pack — multiple diameters for switching between roughing and finishing.

Ball Nose End Mills

What it is: Instead of a flat tip, a ball nose end mill has a rounded end. This leaves smooth, curved surfaces.

Best for:

- 3D carving

- Reliefs and topographic maps

- Organic shapes and contours

- Finishing passes

Materials: Wood and MDF (most common), plastics, foams, and soft metals with shallow stepdowns.

When to use it: Whenever you want a smooth, flowing surface instead of visible steps. Typical workflow: rough with a larger tool, then finish with a smaller ball nose for fine detail.

Helpful pick: TwoTrees 15-pcs CNC Router Bit Set — includes ball nose cutters and other common shapes.

Upcut, Downcut & Compression Bits

These bits look similar, but the spiral direction of the flutes dramatically changes cut quality and chip evacuation.

Upcut Bits

- Action: Flutes pull chips upward out of the kerf.

- Use for: Deep cuts and plastics where chip evacuation matters.

- Tradeoff: Can fray the top surface of wood (tear-out).

Downcut Bits

- Action: Flutes push chips downward into the material.

- Use for: Clean top surfaces, especially in plywood and veneers.

- Tradeoff: Chips compact in the slot; limit depth per pass.

Compression Bits

- Action: Hybrid geometry — upcut at the tip, downcut above it.

- Use for: Clean edges on both top and bottom faces of sheet goods (plywood, MDF, laminates).

- Tip: Make sure your DOC engages the compression zone (past the upcut length) for best results.

Helpful pick: TwoTrees Groove Cutter Set — a versatile pack of spiral cutters for precise groove work and clean edges.

V-Bits

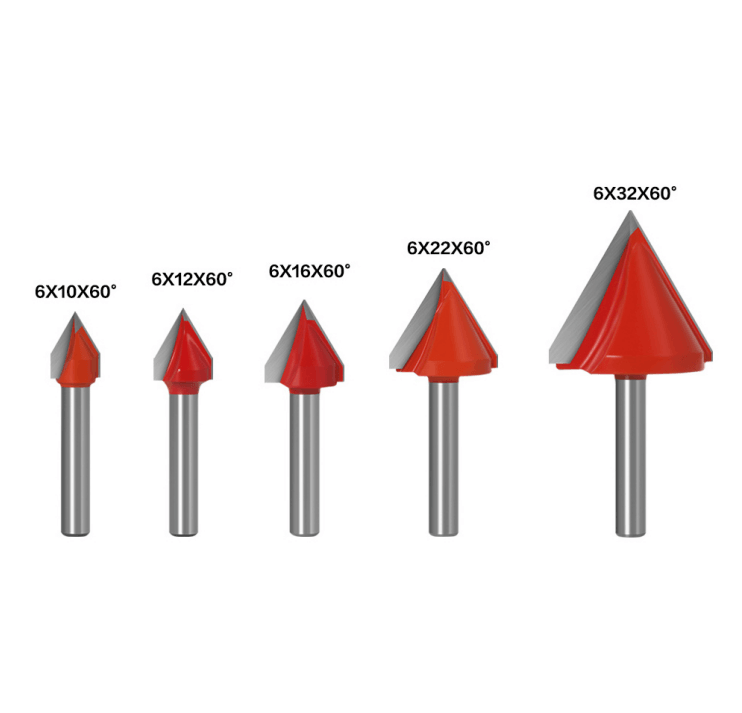

What it is: A V-bit has a tapered, V-shaped tip. Common angles are 30°, 60°, and 90°.

Best for:

- Lettering and engraving

- Sign-making

- Inlays

- Chamfers and decorative surface cuts

When to use it: Any time you want sharp detail and angled lines — carving text into wood for a sign, or creating geometric patterns. Angle choice cheatsheet: 60° for finer detail and narrower lines; 90° for bolder text and wider fills.

Helpful picks:

- TwoTrees V-Groove Cutter 90° — ideal for bold text and larger engraving.

- TwoTrees V-Groove Cutter 60° — sharper angle for fine lettering and detail work.

CNC Router Bits vs End Mills

Terminology: “End mills” were developed for metal milling machines; “router bits” for woodworking routers. On a CNC router, the terms are often used interchangeably because both shank-style tools can be held in a collet and driven along toolpaths.

Geometry: End mills often feature more flutes (2, 3, 4+) and edge prep optimized for metals. Router bits commonly use 1–2 flutes for better chip clearance in wood and plastics.

Shank sizes: Router-friendly sizes like 1/4″ and 1/8″ are most common on hobby CNCs. Industrial end mills span a wider diameter/shank range.

Materials: End mills (carbide/HSS) are built to handle metals; router bits are optimized for wood, MDF, laminates, and plastics.

Practical takeaway: On a CNC router, you’ll often use “end mills” that are effectively router-compatible. The name matters less than the geometry you choose for your material and cut type.

Quick Reference Table

| Tool Type | Best Use Case | Key Advantage | Example Product |

|---|---|---|---|

| Flat End Mill | Pockets, slots, edges | Flat bottoms, sharp edges | Endmill Variety Pack |

| Ball Nose | 3D carving, reliefs | Smooth contours, rounded finish | 15-pcs Router Bit Set |

| Upcut Bit | Deep cuts, plastics, chip clearing | Fast material removal | Groove Cutter Set |

| Downcut Bit | Veneer, plywood | Clean top edges, less tear-out | Groove Cutter Set |

| Compression Bit | Sheet goods (MDF, plywood, laminates) | Clean top & bottom surfaces | Groove Cutter Set |

| V-Bit (90°) | Sign-making, engraving, chamfers | Bold detail, clean lines | V-Groove 90° Cutter |

| V-Bit (60°) | Fine engraving, inlays | Sharp detail, narrow cuts | V-Groove 60° Cutter |

Building a Starter Set

If you’re just getting into CNC routing, here’s a recommended starter kit:

- Flat end mills (1/4″ and 1/8″) for pockets and contours

- Ball nose end mill for 3D carving

- Compression bit for clean plywood cuts

- V-bit (60° or 90°) for engraving and detail work

With just these four types, you can cover nearly all common CNC projects — signs, furniture parts, 3D art, inlays, and more.

Explore TwoTrees CNC Router Bit Collection

Conclusion

CNC routers are powerful tools, but the bit you choose determines the final finish:

- Use flat end mills for pockets and sharp edges.

- Switch to ball nose bits for smooth 3D carving.

- Pick upcut, downcut, or compression bits based on material and surface quality needs.

- Choose a V-bit when engraving or making decorative cuts.

You don’t need dozens of exotic bits to get started. A core set of flat, ball nose, compression, and V-bits — like those in the TwoTrees Endmill Variety Pack and TwoTrees 15-pcs Router Bit Set — will cover the vast majority of projects.