Project Overview

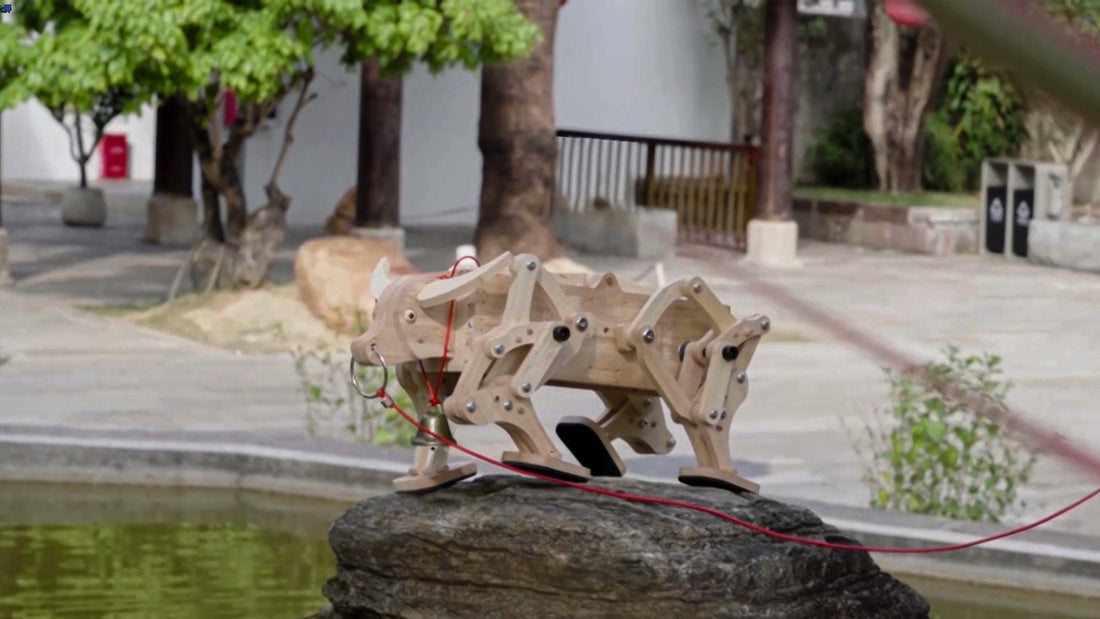

This CNC woodworking project brings ancient Chinese mechanics to life through modern CNC technology. The final result is a movable wooden ox-horse—an automaton toy that functions as both a piece of artwork and a playful gift. Inspired by the traditional Muniuliuma design, this project blends history, creativity, and engineering.

- Type: Toy / Artwork / Gift

- Concept: Revive traditional mechanics with CNC carving

- Uses: Display piece, interactive toy, or handmade gift

CNC Machine and Settings

For this project, we used the TwoTrees TTC6050 CNC Router. With its large 600 × 500 × 100 mm work area, the TTC6050 provides enough cutting space for toy parts, automata, and other medium-sized wooden projects.

Machine Specs for This Build:

- CNC Machine: TwoTrees TTC6050

- Work Area: 600 × 500 × 100 mm (23.6 × 19.7 × 3.9 in)

- Materials: 20 mm pine board, 50 mm pine block, brass bells

- Cutting Tools: 3.175 mm straight flute end mill, 3.175 mm V-bit

-

Feeds & Speeds:

- Cutting feed: 4000 mm/min

- Plunge feed: 1000 mm/min

- Depth per pass: 0.5 mm

Design and Files

The ox-horse automaton was designed in Carveco, a CNC design and CAM software ideal for 2.5D and 3D carving projects.

- File Format: STL

- Customization: Optional logo engraving for personal or branded projects

- Flexibility: The STL file can be resized or modified to fit different CNC router dimensions

Project Difficulty and Skills Needed

This is an intermediate-level CNC project. It’s suitable for hobbyists who have already completed simple CNC carvings and want to step up to a more mechanical design.

-

Estimated Time: About 2 hours total

- CNC carving: ~30 minutes

- Post-processing: ~1.5 hours (sanding, finishing, assembly)

- Required Skills: Sanding, applying wood wax or finish, basic mechanical assembly for movable joints

Assembly and Finishing

After cutting the parts on the CNC, lightly sand all edges to ensure smooth movement. Apply wood wax or oil for protection and to bring out the grain of the pine. Assemble the moving parts, attach the brass bells, and test the motion. The result is a charming automaton that moves realistically when pushed or pulled.

Media Assets

Here’s a look at the finished project:

Watch the full build in action:

▶ Video Demo

Conclusion

The CNC-carved movable wooden ox-horse is more than just a craft project—it’s a bridge between history and technology. Using the TwoTrees TTC6050, you can create a working automaton that delights as a toy, impresses as a display piece, or makes a thoughtful handmade gift. For hobbyists looking to expand their CNC woodworking skills, this project offers a perfect blend of challenge, creativity, and reward.